In order to understand the purpose of a hydraulics cylinder, it is necessary to first understand the basic principles of hydraulics. Hydraulics is the branch of science that deals with the mechanical properties of liquids. The word hydraulics is derived from the Greek word for water, hydro. Read on below if you really want to learn more about this magnificent device.

What is a Hydraulics Cylinder – The Basics

The basic principle of hydraulics is that fluid pressure exerted on a confined fluid is transmitted throughout the fluid and is equal in all directions. This principle is used in the operation of a hydraulics cylinder. You have to understand its components, how it works, and how it can be beneficial to you and to what you do.

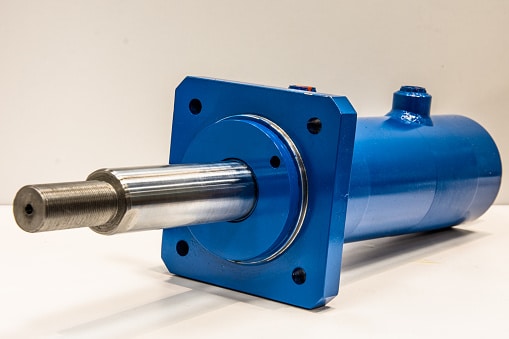

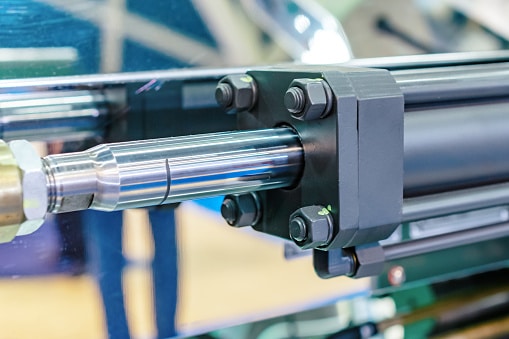

A hydraulics cylinder is a device that uses the principles of hydraulics to create linear motion. The cylinder consists of a piston that is sealed in a cylinder. The piston is connected properly to a rod, which is used to transfer the motion created by the piston to another object. It allows the transfer to go through easily and consistently so that your machine or equipment can function smoothly.

Hydraulic cylinders work by using fluid pressure to generate linear force and motion. This is accomplished by using a piston inside a cylinder, which is filled with fluid. When the piston is extended, the fluid is forced out of the cylinder, which creates linear force and motion. The functionality of this device sounds simple, but it definitely plays a great role in the functionality of your machine or equipment.

Hydraulic cylinders are an essential part of many industrial and construction applications. They are used to provide linear force and motion, and can be found in a variety of settings, from automotive manufacturing to material handling. It is an essential part that can never go wrong. If you are going to get a hydraulic cylinder, make sure to get the one with the best quality. It should be made from the best possible material so that it can withstand great force and provide great functionality.

Uses of Hydraulic Cylinders

There are many different types of hydraulic cylinders, each with their own unique advantages and disadvantages. The type of hydraulic cylinder that is best suited for a particular application will depend on a variety of factors, including the required force and motion, the operating environment, and the available space.

Some of the most common types of hydraulic cylinders include single-acting cylinders, double-acting cylinders, and telescopic cylinders. Single-acting cylinders are the simplest type of hydraulic cylinder. Today, manufacturers made available lots of options for you. You can easily find the right hydraulic cylinders for your equipment.

Hydraulic cylinders can be used for lifting, pushing, pulling or holding objects in place. In construction, hydraulic cylinders are used to level and grade soil. In agriculture, they are used to operate farm equipment, such as tractors and combines. In manufacturing, they are used in assembly line operations to move parts and products.

Hello, My name is Shari & I am a writer for the ‘Outlook AppIns’ blog. I’m a CSIT graduate & I’ve been working in the IT industry for 3 years.